Observed problems and performance losses

For industrial workshops that have not yet gone through a digitization phase, the time spent on data entry represents, on average, one and a half years of work for a full-time employee.

The observation made by META 2i throughout its 30 years of experience is unequivocal: the way in which the time of seizure of production is carried out, then its rise in the ERP represent a loss of productivity and time consequent for an industrial.

Historically, many workshops work with a paper sheet on the shop floor. The operators manually write the data related to the production carried out during their shift:

- Quantity produced

- Rejected quantity

- Test bench report

- Maintenance sheet

- Quality sheet…

Most often, the workshop manager is then responsible for retrieving these sheets and manually re-entering the data in the ERP or in the software associated with the production data feedback.

This method represents a waste of time, as well as an error rate linked to this double entry of production data.

The zero paper method: how to save time in the workshop?

In an approach of continuous improvement and operational efficiency, the MES software allows a revolution of the method of time entry in the production workshops.

The goal is simple: to eliminate all the Excel spreadsheets as well as the paper sheets of the workshop by integrating a single software that gathers all the applications necessary for the good operational functioning of the production workshop.

How does this work for operator production input?

This translates into an intuitive software interface that can be adapted to the industrial process concerned. The operator will be able to directly enter the data related to his production.

All the forms and reports will be digitized and the information will be automatically sent to the ERP and/or the desired recipient.

This will also allow a perfect traceability of the information, thanks to an integrated audit trail, as well as a search function for past production orders.

Finally, anyone who needs this information will be able to have it available on their computer at their workstation, but also on their smartphone or tablet, and all this with certified data security.

By eliminating the double entry of production information, we halve the time required for this entry, while drastically reducing the related error rate.

What are the other benefits of going paperless?

MES reduces my data entry time, but why else should I banish paper from my shop floor?

The first point is a simple one: using paper has a cost. It must be supplied and requires the purchase and maintenance of equipment related to its use (printer, scanner…).

It also requires human logistics: it must be printed, brought to the place where it will be used, completed manually, etc.

Moreover, it must be continuously updated, it can also be lost or damaged.

All this represents a cost in time that can be saved.

Paperless saves me money, but it doesn’t directly improve my productivity?

The paperless method also has a direct impact on the productivity of the workshop.

Firstly with the data entry time as we have seen, but also thanks to the centralization of essential documents for production.

The MES software allows an efficient and adapted document management.

Let’s take an example: an operator receives a production order for a certain part. To carry out his work, he needs documents (drawings, reports or tracking sheets, quality sheets, etc.). He will be able to find them directly on his workstation thanks to the search function, and even fill in the forms directly in the MES software.

MES is a fundamental player in the continuous improvement and performance of industrial workshops. We estimate that 70% of industries that have implemented an MES have achieved a growth of at least 10% within 3 years.

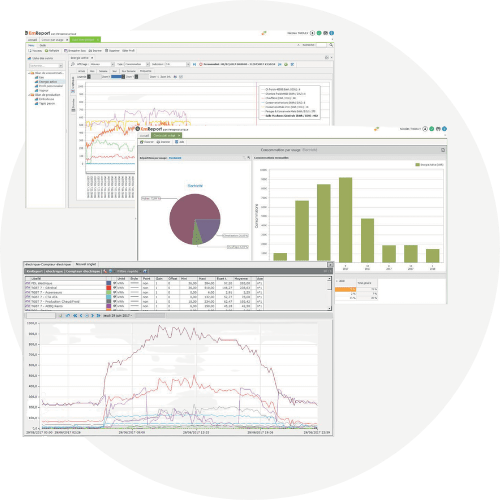

KmProd, the MES suite from META 2i

These applications are only a small part of what our software suite offers. To discover all the features of KmProd, contact us.

By choosing the KmProd solution, you will benefit from a medium-term support (5 years) to constantly improve your industrial processes !

KmProd distinguishes itself from its competitors by its flexibility! Adapting up to 50%, it is possible to set up KmProd whatever your sector of activity.

Follow your production in real time and take advantage of the multiple real and multi-dimensional returns on investment (ROI).

KmProd distinguishes itself from its competitors by its flexibility! Adapting up to 50%, it is possible to set up KmProd whatever your sector of activity.

Follow your production in real time and take advantage of the multiple real and multi-dimensional returns on investment (ROI).