In this article

As the cost of energy continues to rise in France, it is becoming increasingly important for companies to find ways to reduce their energy consumption.

There are many ways to do this, including energy efficient appliances, waste heat recovery and process optimization.

> In this article, we’ll look at some of the ways companies can save energy and reduce their carbon footprint in the process. We will also look at the potential savings that can be realized by implementing these measures.

How much can a company save by optimizing its energy consumption?

25 %

Our experts observe up to 25% energy reduction

12 à 15 %

According to field analyses, the average observed reduction is 12 to 15%.

centaines de milliers

This represents several hundred thousand euros per year for some plants.

Increase your operators to save money? - Case studies

Some companies have chosen to increase their operators’ wages by 25% on Saturdays during off-peak production hours. One day a week is then off.

Thus, from an electrical point of view, the consumption is less expensive at these times. The total cost will then be cheaper than during the week.

The advantages of the KmProd MES software - Case studies

The scheduling that KmProd allows allows to use only one oven if there is a reduction in production. The processes must be grouped together by prioritizing the most energy-intensive productions and then reducing the heat. The MES solution allows you to optimize the output of these parts that will cool the oven while avoiding unnecessary heating.

What consumes the most energy in a company? How to reduce consumption?

Building heating for users

Solution

Concentrate the teams, move to telecommuting when the missions can be done remotely.

Bad insulation

Solution

Hire a company to insulate or renovate the walls and ceilings of the premises.

Open spaces

Solution

Reduce their surfaces and use different heating circuits to use the heated air and warm the surfaces.

Anecdote of a META 2i customer

One of our clients wanted to make available the surplus heat he created in his furnaces. He donated this heat to a community by heating the town of Constellium in Issoire. More information on this article

7 simple steps to reduce energy consumption in a company: Actions to implement now!

1

Before anything else, it is important to inform your teams and even your service providers about the actions that have been implemented and explain their benefits. These process changes also require awareness.

Before anything else, it is important to inform your teams and even your service providers about the actions that have been implemented and explain their benefits. These process changes also require awareness.

2

Optimize processes to reduce production costs. Attention, it is essential to keep the same quality and efficiency.

Optimize processes to reduce production costs. Attention, it is essential to keep the same quality and efficiency.

3

Install containers to encourage recycling of materials. Not to mention the cost of redesigning or transforming. You must question the origin of the materials and think about the "global process".

For example: a material that comes from a less distant region or country will cost less overall (production, transportation, delivery, etc.).

Install containers to encourage recycling of materials. Not to mention the cost of redesigning or transforming. You must question the origin of the materials and think about the "global process".

For example: a material that comes from a less distant region or country will cost less overall (production, transportation, delivery, etc.).

4

Invest in new machines and train in new technologies. Previously, energy consumption was not an issue. The machines did not integrate these issues. Today it is necessary to have reliable, recent tools in order to respect new standards and to be up to date in terms of technology compared to your competitors. These investment choices are important for your production.

Invest in new machines and train in new technologies. Previously, energy consumption was not an issue. The machines did not integrate these issues. Today it is necessary to have reliable, recent tools in order to respect new standards and to be up to date in terms of technology compared to your competitors. These investment choices are important for your production.

5

Gather feedback from your teams. Through these changes, you will surely get feedback or proposals from your teams. You must analyze and adapt your methods according to their feedback. You must listen to them in order to make them aware of the changes.

Gather feedback from your teams. Through these changes, you will surely get feedback or proposals from your teams. You must analyze and adapt your methods according to their feedback. You must listen to them in order to make them aware of the changes.

6

Analyze its field data and come up with actions to be taken. Meta2i helps its users to understand their data. Our experts know how to interpret your numbers so that the best decisions are made with you.

Analyze its field data and come up with actions to be taken. Meta2i helps its users to understand their data. Our experts know how to interpret your numbers so that the best decisions are made with you.

7

Limit paper printing by reminding you to print only when necessary (in your emails or directly on your printers).

Limit paper printing by reminding you to print only when necessary (in your emails or directly on your printers).

Other sources of optimization for industries in all types of sectors

Identify your electricity sources

- Program on/off times on certain appliances or even integrate sensors so that a detector is warned when an employee arrives (turn on and heat up and not standby for example).

Rethink the use of your heating system in your offices in order to know if it is better to reduce the temperature of your premises by 4 or 5 degrees on weekends or to heat them on a day during the week when there are the most employees? - As a reminder, heating poorly insulated rooms is a waste of money. Prioritize the insulation of your rooms to avoid heat loss.

Pour rappel, chauffer des locaux mal isolés est une perte d’argent. Prioriser l’isolation de vos pièces afin de ne pas avoir de déperdition de chaleur.

- Training on equipment shutdown: It is essential to do prevention internally and to create documentation so that the teams master their equipment.

> For example, in an industry, if some employees forget to shut down ovens, this can not only create quality problems, but also consume energy unnecessarily. On the other hand, in some specific cases, the temperature needs to be constant, the pressure as well. Always maintain the quality or allow a slight variation, but never lower the range.

Case study after production analysis thanks to KmProd: the heating of an oven during a whole weekend.

Each production stoppage saves energy.

> If we save 2 days out of 7 of energy consumption, that is to say 20-25 % of theoretical reduction, we observe that in practice it is possible to save 15 % (our KmProd users use for many of them, electric or gas ovens).

Manage your water consumption and quality

It is probably not necessary to have clean water in your entire industry. A production department or workshop can perhaps do without drinking water in order to function. It can also use recycled water for heating.

Recycle your consumables

Besides reducing paper use or having a zero paper policy, there are other practices to control consumables.

Example of a customer case observed thanks to KMProd: The tools of a workshop were cleaned by “default” in a soda bath. However, this is an expensive consumable. Some tools do not need to be washed to continue to be used.

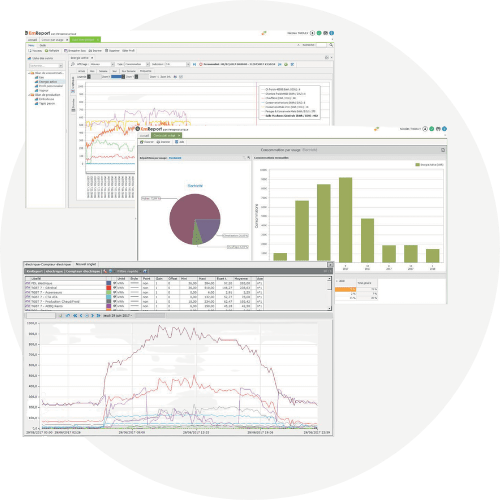

Bonus : Why use an MES software like KmProd in industry ?

A solution such as KMProd can help you to find the best compromise and to anticipate according to a production according to your data.

An MES software will allow you to optimize your production workshops. KMProd’s expertise continues in the consulting and publishing of its production monitoring software packages.

Our MES solution is open and scalable. It includes :

The follow-up of the whole production.

The management of the 4 resources of the company (people, energy, machines and material).

Industrial and energy optimization.

Continuous improvement of your processes.

A multi-site, multi-language software.

An SDK for product evolution.

To discover our operational features, go to our page.

Conclusion

In the fight against rising energy costs, it’s important for industrial companies to find ways to reduce that budget. The key? Asking the right questions, educating employees on the importance of energy conservation, prioritizing needs and budgets, and finally, implementing devices to reduce energy consumption.

It may seem like a challenge, but there are many ways to reduce your expenses. This is the mission of META 2i’s experts.

If you would like to learn more about using MES software to manage your energy actions and save money on your production, contact us today.

David Fermandes

META 2i President