What is MES software?

MES software (or Manufacturing Execution System) is a production control software invented in the 1980s. The ISA (International Society of Automation) contributed to standardize what these tools could do and how. Growing especially since the 1990s, it has evolved over the decades and has taken an important place in the Industry 4.0 process.

MES differs from ERP (Enterprise Resource Planning) by its “automation” orientation and complements the “planning” dimension of ERP, which does not integrate the same variables and parameters.)

If the ERP represents the lights on the dashboard of a vehicle, the MES is the on-board software of the car (it measures the tire pressure, the fluid levels, the injection and other “invisible” but very present parameters).

It is a computer system that, by collecting real-time production data from a factory or shop floor, is able to connect, monitor and control complex manufacturing systems and data flows on the shop floor for better productivity and performance.

The main functions of an MES solution are defined by the ANSI/ISA-95 standard, which defines the role of MES software. Here are the 11 functions of the ISA95 standard:

Personnel management

Be able to manage the skills and qualifications of your staff, and those required for your products and/or operations.

Quality management

Control and monitor the quality of the manufacturing process, to be part of an SPC (Statistical Process Control) approach. Digitize the quality controls in the workshop.

Product and batch tracking

Manage all production data flow in real time between the ERP and the shop floor to facilitate process execution.

Maintenance management

Manage the planning of the various preventive and periodic maintenance operations in order to reduce the impact on manufacturing and facilitate interventions.

Data collection and acquisition

Obtain the different events and production data in real time from the different tools (automats, machines and human resources)

Scheduling

Build a planning system capable of providing a global view of orders in real time thanks to a connection to the different equipment.

Process management

Provision of digitalized tracking sheets as well as the manufacturing steps.

Document management

Provide the operator with the documents (PDF, plans, schematics) necessary to carry out his work. Digitize the documents with a provision adapted to the industrial.

Resource management

Define, manage and monitor human, machine, material and energy resources according to their status (in production, down, stopped, material shortage, etc.).

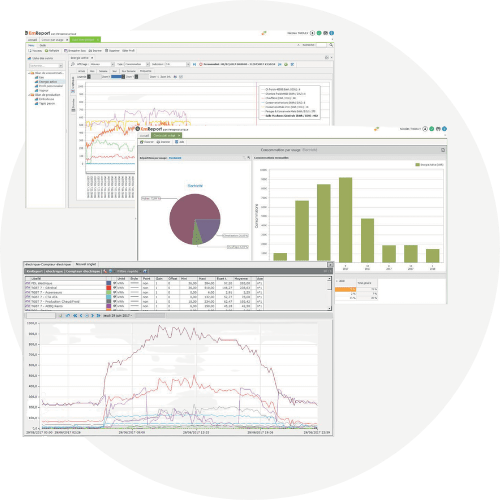

Performance analysis

Follow in real time the different times linked to the production in order to calculate the key indicators of the production and notably the TRS indicators.

Product traceability and genealogy

Obtain the manufacturing data associated with a batch from the raw material to the assembly of these components.

META 2i accompanies you on all the stages of the installation of your MES software:

Consulting

Consulting aims to give you a concrete approach to Industry 4.0 by offering real solutions to your problems.

Our teams will proceed to a complete diagnosis of your company in order to establish an action plan adapted to the needs and the available resources of the structure. We will then accompany you in order to establish a complete and customized specifications for a 4.0 project.

It is important to know that this practice does not commit you in any way! We are here to advise you on your choices and the future of your company by being the closest to you on a daily basis.

Implementation of a customized MES : KmProd by META 2i

META 2i will then propose you its global offer in order to answer your need step by step.

KmProd distinguishes itself from its competitors by its flexibility! Adapting up to 50% to your process, it is possible to set up KmProd whatever your sector of activity.

Update and follow-up of your needs

By choosing the MES KmProd, you choose a solution that is regularly updated and that accompanies you daily on your current and future projects.