In an increasingly connected world and with the arrival of 5G, which is being deployed very quickly, production habits will have to be updated.

With its extremely low latency, 5G will find a large number of applications, with upheavals already known in telemedicine, transport, or in industry with the factories of the future, which are being built today if you do not want to be part of a past that may be prosperous but is unsuitable in today’s world.

A new industrial world?

Technological evolutions have caused industrial revolutions in every era. The latest ones in the field of industry have been driven by NTIC, Industry 4.0, Big Data (without forgetting the emergence and importance of standards).

Nevertheless, the needs and objectives of industrialists have remained the same, i.e. to control their production as well as possible, in particular thanks to the collection and availability of information. This information must be provided to the right actors and at the right time in order to increase productivity and quality

The MES of tomorrow will be web-based:

Today, manufacturers need to have mobility in their workshops. The 5G + Big Data formula can only be won through maximum connectivity. This is why it is becoming imperative for MES solution editors to develop a WEB version of their software to meet these new needs.

This mobility will impact the traditional working methods of operators who will have to adapt to optimize this evolution. The impact will be on 3 points in particular:

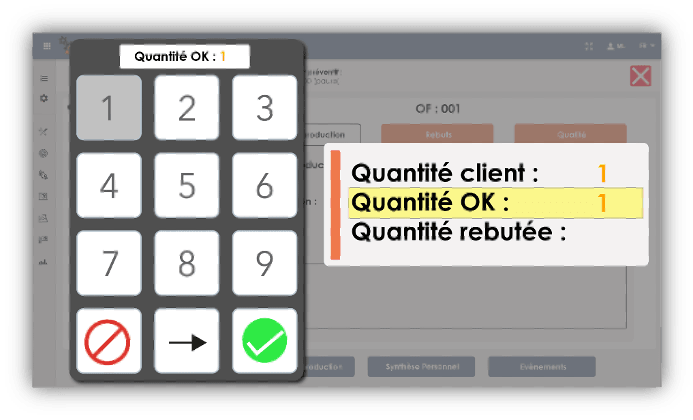

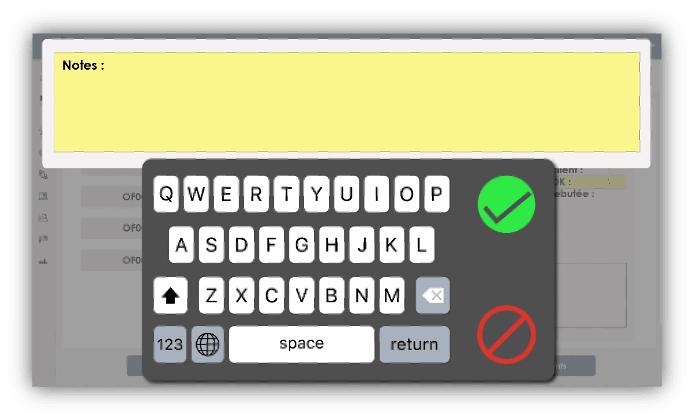

- The necessary association of a computerized gesture with a physical gesture

- Bringing the IT process as close as possible to the physical process

- A process centered on the operator because it is he who will enter the right information at the right time

The advantages of a MES in WEB version :

- Mobility allows data entry at any time and any place

- Several media can be used for different purposes: Tablet, cell phone, scanner, radio terminal…

- A WEB version with a good network allows more advanced uses: photos or videos of parts, machines, rejects for quality control, to report a breakdown and its cause (via the sending of machine data or photos / videos)

- Greater reliability of information by reducing the rate of data entry errors

- The addition of videos, tutorials, didactic content (in augmented reality) and other essential demos to quickly understand the workstation and the instructions in real time.

Concrete example of mobility via KmProd :

A company having a problem with the follow-up of its stock called upon META 2i to find the most adapted solution. The company was experiencing complications with the traceability of its stock, which had the impact of lengthening the duration of supplies (for example: a supply supposed to be made in ten minutes could last more than an hour).

The KmProd solution:

Implementation of a process for operators to scan in real time the content (with a QR codes system), the container and its location in order to know the location in real time of the stock in the factory.

The benefits of this action:

- Significant time saving

- Improvement of the quality of the stock

- Easier inventory to perform

- Total elimination of data entry or re-entry errors (total stock reliability)

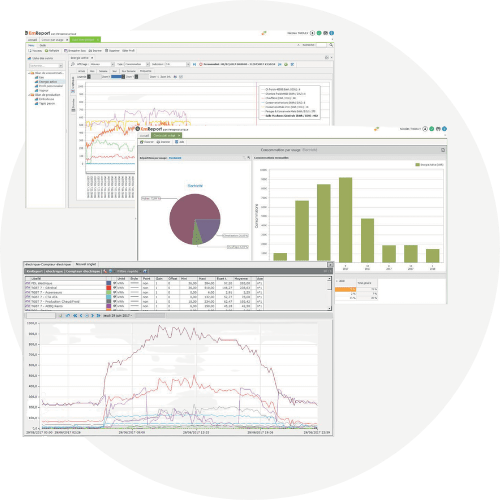

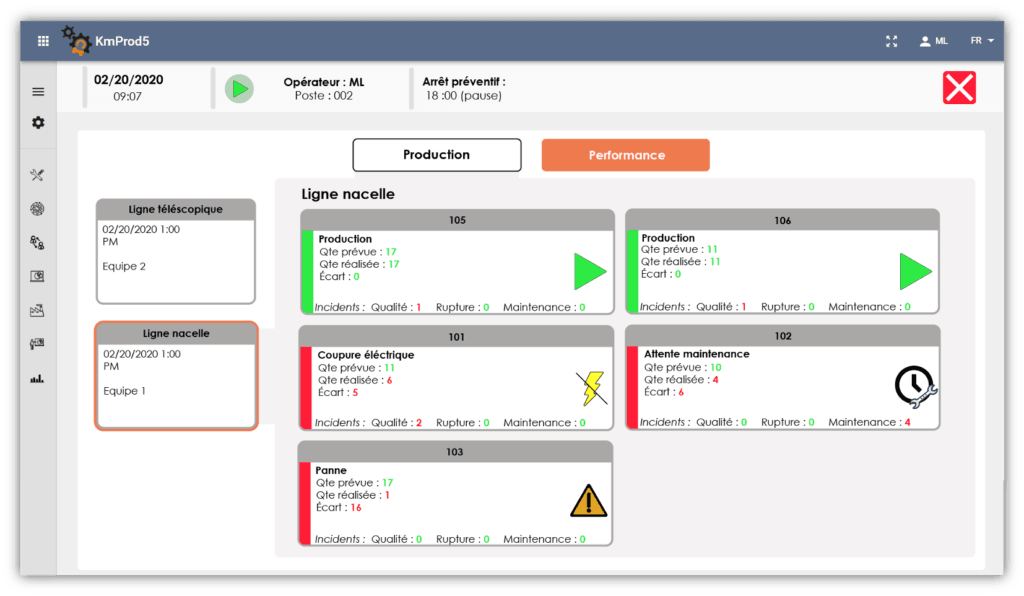

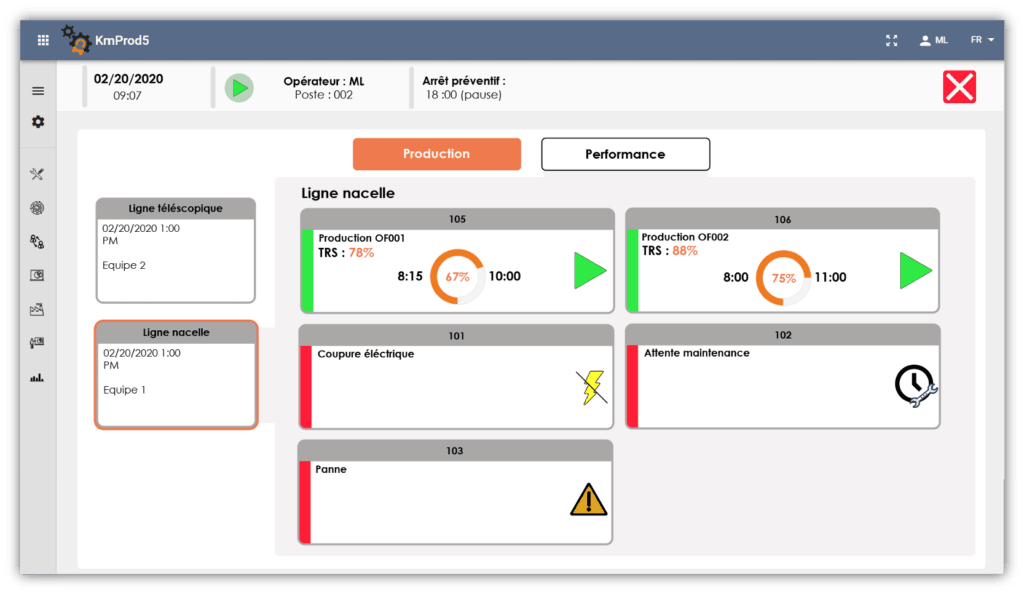

Example of KmProd screens in WEB version:

To go further, KmProd also offers a web version of its workshop visualization. This will allow your managers to access information on production and performance in real time at any time:

Conclusion :

Our customers have already chosen the web version of KmProd for all or part of their production. We deploy and adapt our web version to specific and generic needs in order to give you an ideal tool, both :

- simple and complete

- readable and controllable in several languages

- Multi-sites and multi-users

- On several terminals (tablets, PC, Smartphones)

Finally, the security of your data is our main concern, which is why we use the tools of the market leaders with uncompromising standards.