Quality is very often perceived as customer satisfaction, but is this sufficient (we all have our biases depending on our job and our position in the structure). From an industrial point of view, quality management is an objective whose standards are precisely fixed (at a certain date, by recognized organizations).

Industrial quality is the result of a production process that follows a nomenclature through the various stages of product design to achieve and control the desired level.

We could talk at length about the definition of quality, which is unique to almost everyone. It is also possible to have a tool that acts as a consensus actor, the MES software.

When we talk about MES software, we mostly think about real-time manufacturing monitoring and rarely about quality management. As a continuous improvement tool, quality management remains within the scope of MES, but is often seen as an auxiliary function that can be covered by other information systems in parallel with MES.

However, quality has a direct impact on performance and OEE (Overall Equipment Effectiveness). That’s why a good quality management integrated to the MES software will allow quality managers and operators to identify all causes of non-quality, to capture critical data and to get feedback to improve efficiency and effectiveness.

Quality management is at the heart of performance improvement. It ensures better monitoring of all quality control processes in the factory, particularly through the integration of lean management tools.

Quality management in KmProd :

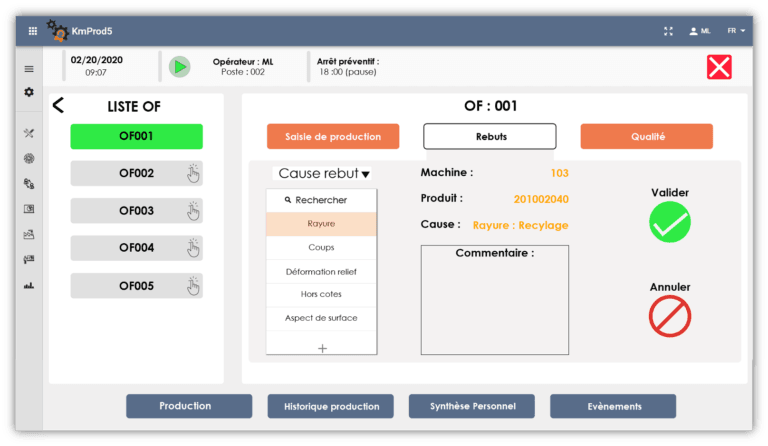

Thanks to the MES software, production monitoring can be done in real time and this will also be the case for quality management. The KmProd MES software will allow operators to directly indicate a quality problem on their production and to enter a cause for scrap. He will be given examples of causes (from our statistical models based on 30 years of data) but will also be able to comment on this problem if necessary.

A quality control can be set up following a scrap entry, in the form of a pop-up.

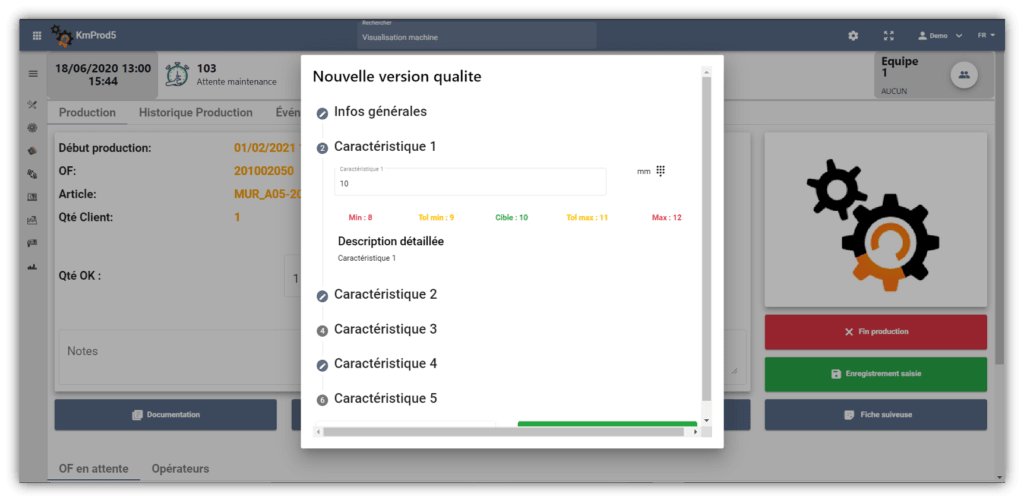

It is interesting to couple quality data capture with connected tools, such as calipers, torque wrenches or other metrology devices. These tools will send the measured data immediately to KmProd, which will eliminate the human control step, boring, unpleasant and generating inaccuracies. The goal is always to save time and reduce the error rate.

The integrated quality control editor also allows the addition of documents, images and videos, as well as many types of characteristics, for maximum customization and appropriation by the operators, even if they are temporarily present.

To go further, META 2i offers you the PDCA and FMEA modules integrated in its MES KmProd software. These modules will allow you to target and identify the problems encountered in the workshop and to remedy them as efficiently as possible.

For more information: PDCA and FMECA

KmProd distinguishes itself from its competitors by its flexibility! Adapting up to 50%, it is possible to implement KmProd regardless of your sector of activity. We will be able to meet all your different quality management needs as well as your entire industrial process. Do not hesitate to contact us to explain us what is the challenge you want to take up.