In this article

In a world where energy efficiency and the reduction of greenhouse gas emissions are becoming more and more important, having a software solution that allows you to save energy in your industrial process is essential.

But how exactly does MES software help you save energy?

Identify the most energy-intensive workshops and departments

First, it is important to identify the most energy-intensive departments in your industry.

For Meta2i‘s customers and partners (and especially those producing in France), we have observed that the departments that consumed the most energy were :

Furnaces and melting processes

Electrolysis, Anodization

Processes requiring water cooling

Pickling baths

This is because the furnaces and smelting processes use a lot of electricity or gas for their operation.

In the case of electrolysis and anodizing, these workshops are so energy-intensive that it is not uncommon for companies to postpone their production, sometimes by several weeks. Since they cannot find other solutions or optimizations (we will see which ones later), they limit themselves to the bare minimum or to the most profitable productions.

In 2022, some companies have multiplied their energy consumption bills by 2. It is essential to fully understand the commitments and contracts that bind you to your supplier. Take the time to read them again!

How can industrial production software help you?

8 actions : How does an MES software allow to control and adjust its energy consumption?

1

The software allows you to collect production data in real time. This gives you a reliable idea for your audits, analyses and optimizations. It guarantees a finer production follow-up close to your reality.

2

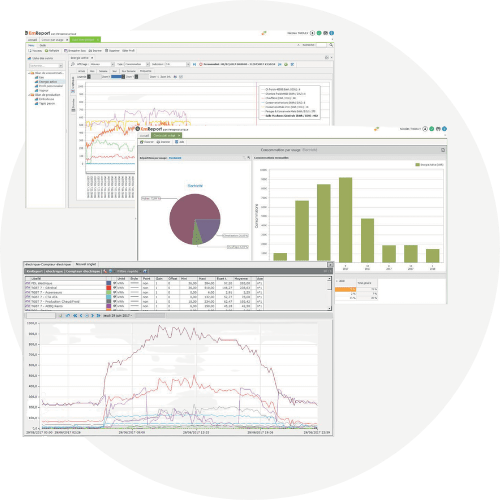

Thanks to the production calendars, you have a quick overview of the workshops in service and their next working weeks. At the same time, you have an overview of consumption per workshop, per type of production and per machine or tool.

3

Our graphical interfaces have been designed to give you access to your statistics in a few clicks. Thanks to the tables and infographics at your disposal, you will be able to know which energy (or combination of energies) has been used by a production.

Our graphical interfaces have been designed to give you access to your statistics in a few clicks. Thanks to the tables and infographics at your disposal, you will be able to know which energy (or combination of energies) has been used by a production.

4

A MES software allows you to observe the data acquisition. You will finally know to what extent your production is profitable once the energy consumption is deducted. You will then be able to transpose your consumption data, but also your production data and probably adjust your processes to be more profitable.

5

Testing to know when to produce and how to "gain degrees"? Within KmProd and KmEnergy, you have the possibility to cross-reference data according to different scenarios and production tests. For example: identify off-peak hours, should you produce at night? If an oven drops a few degrees, is the quality of the production impacted? If so, isn't the loss of a few parts more interesting financially than the additional consumption costs resulting from the difference? The employees responsible for analyzing these data and determining their measurements are comfortable with our interfaces. The available infographics and tables are customizable and support multiple languages and alphabets

6

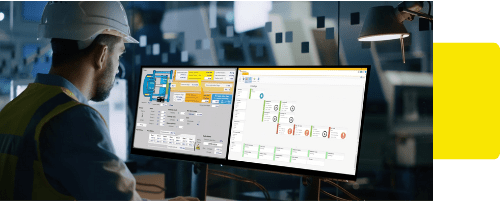

Drawing a diagram of your plant may seem trivial, but it is necessary to have an overall and precise vision of your operation. With an MES software such as KmProd, you will be able to create maps and tree diagrams of your workshops, lines, machines and equipment. All that remains is to collect data from your production and structure it (most of the companies we work with already have a lot of data. This data is often poorly exploited and poorly queried).

Drawing a diagram of your plant may seem trivial, but it is necessary to have an overall and precise vision of your operation. With an MES software such as KmProd, you will be able to create maps and tree diagrams of your workshops, lines, machines and equipment. All that remains is to collect data from your production and structure it (most of the companies we work with already have a lot of data. This data is often poorly exploited and poorly queried).

7

Review your instructions and processes. Do you have concrete feedback on what you have implemented internally? The software will be able to adapt your instructions to your production.

8

In terms of managing your temperatures, between the use of ovens heating and heat loss, you should know that the curves and figures given by the MES software can, for example, make you reduce the use of certain machines by a few degrees during large productions. Case in point: during an important production run, can we reduce the temperature by 10 degrees? If the OF lasts longer, but consumes less energy, is it profitable for your factory? The times raise new questions. MES helps you to find the answer.

To which business sectors is this performance monitoring software aimed at?

What size of company?

Whether your workforce consists of a dozen employees or several thousand people, the MES energy monitoring software is used to optimize all sizes of companies in their production by improving the quality, traceability of products and processes.

What type of industries?

The MES is ideal for the aluminum, food, plastic, medical, glass, precision engineering, etc. sectors.

What is the objective?

The reduction of costs and time concerns most workshops. Paperless is also a real transition and evolution for industries (and well beyond the simple saving of paper). It is especially about avoiding data entry times and errors.

In general, what are the first actions following the implementation of an MES?

Machine times

In order to identify the SRTs, it is relevant to measure the effective times on a station. Is it better for an operator to enter the data manually 1 hour before a production stop or to use a machine performing a complete analysis?

Rapid design of an action plan

The MES helps the decision maker and operator to define which task has priority.

Optimize the switching on and off of ovens

In order to reduce their bills, customers stop their furnaces on Thursday/Friday and only turn them on again on Saturday/Sunday (off-peak hours). These savings allow us to cover the additional salary costs related to weekend hours and to be more profitable.

Do CO2 reduction and energy saving go hand in hand?

It is often thought that reducing energy consumption can have an impact on reducing CO2 emissions.

The strategy is more complex than that. It is necessary to invest and have a business strategy to optimize 2 or 3 processes that will serve to compensate for the excess of an emission on a stage of the production chain.

It is therefore necessary to think about the process as a whole and create new indicators.

Sometimes a department or workshop will be at its maximum optimization on an execution, it is necessary to go further to ask other questions in connection with these operations: Where does the energy come from? Where are the materials sourced? Are the work teams properly trained?

When you have to choose between carbon emissions and energy savings, there are probably internal investments to be made to make this subtle mix of the two issues while respecting the company’s brand image.

Stay within a goal where you need to maintain, or decrease, current costs while increasing the quality of your production. This can also mean reducing your environmental impact while improving your productivity.

In conclusion

In general, MES software allows you to control your processes remotely, which can further reduce your energy consumption. These software solutions can also help you visualize your energy consumption, making it easier to identify other areas for improvement. To learn more about the benefits and how MES software can help you save energy in your industrial process, contact us today.

David Fermandes

META 2i President