Like most companies, you probably have ERP (Enterprise Resource Planning) software. The main objective of the implementation of this tool is to increase the global performance of the company by understanding and managing it better.

The goal of an ERP is to capture the company’s database in order to insert or modify data in a module that will impact all other modules. For example: the main database will be updated and the modification will be applied to the whole company. The ERP is a global management tool, at the service of business and strategic units.

The MES is a production management software. It collects production data from a factory or workshop in real time. It is able to connect, monitor and control manufacturing systems (with complex data flows). This is valid both at the shop floor level and between different production sites. The result is better productivity and performance for your company.

The complementarity between MES and ERP :

MES and ERP are complementary on different points:

- Data exchange

- Processing and interpretation of collected data

- The reinforcement of production data.

These two softwares can exchange large volumes of data such as production data (operating ranges, OF, references, bills of material, batches and other KPIs) and data on the various equipment (machines, workshops, etc.).

Serve reliable data from the field to the ERP:

The contributions of MES to ERP :

Here is the production process of a company with an MES and an ERP:

The operator launches his OF (Manufacturing Order), he will have at his disposal the necessary information to carry out his process. He can follow the progress of his production order in real time and report problems directly to his workstation.

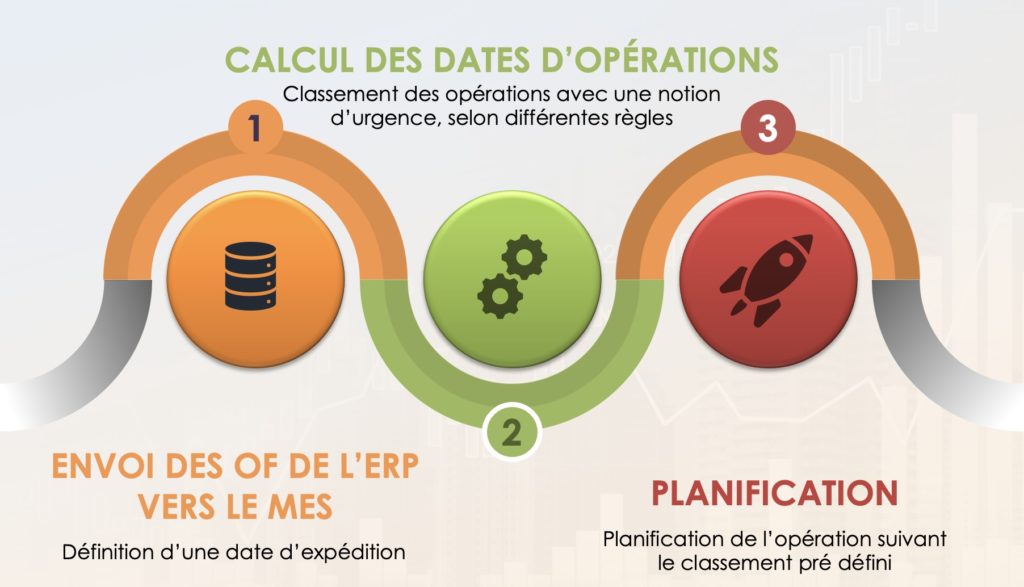

The MES can retrieve his OF directly from the ERP. The MES is also able to retrieve the production schedule from the ERP in order to manage it. The MES will be able to propose an automatic scheduling thanks to these data.

At the workshop supervision level, the manager can use the information available in real time such as production quantities, the number of rejects, the causes of rejects, breakdowns / production stoppages (but also your own business indicators).

All this data can be sent to the ERP so that their collection and processing facilitate management.

Scheduling management:

By retrieving the data collected in the ERP, the MES can propose a scheduling calculated according to the production load and the configuration (stocks, availability / absence and skills of operators, predefined duration of future OF, OF in progress…).

This configuration can be modified according to your choices and alerts can be set up to avoid delays and omissions.

How will KmProd interface with your ERP ?

The KmProd software suite, published by META 2i, has been working with historical clients in several industries for over 30 years. It is constantly developing to meet the needs of each company and their challenges.

Thus, thanks to its multisectorial strategy, the company is able to adapt to the needs of each company. KmProd must therefore be able to interface with all the ERP of the market.

Conclusion :

So No, your MES will not replace your ERP, these tools have different AND complementary functions.

It is possible that sometimes these two softwares are able to produce the same data. Think of it as a consolidation of your management tools, as redundancy in aviation.

MES or ERP? You need a tool that projects you into the future and a tool that tells you where you are in real time.

As for the complementarity of the tools, you should know that KmProd is compatible with the vast majority of ERPs because of the clarity and quality of the data it is able to produce and synthesize.