Manual scheduling management is a reality. Some people say “yes, but for my job it’s a bit special” and others seek to automate (and therefore make more reliable) the organization.

Automating and digitizing also saves time and avoids operator fatigue. In some cases, scheduling managers plan production using Excel spreadsheets with over 10,000 lines. No one can manage this without making mistakes sooner or later, which at best will lead to delays, at worst to quality problems. In addition, there is the human risk of the absence of a key person (the scheduling manager for example) and the risk that no one can take over, even partially.

The solution for your scheduling:

In order to improve and optimize your production capacities, you decide to implement a scheduling software for a more accurate planning of your production orders.

To meet this need, there are 3 categories of solutions:

- Planning via your ERP software through a dedicated module

- APS software (Advanced Planning System)

- MES software with its scheduling module

There is no category that is “better” than the others. The right solution will depend on the context of your company and of course on the control that the company that will accompany you will have of the tool that it deploys on your premises.

You should know that there are specific software for almost every profession. However, you must be careful about one thing. Indeed, some softwares are “adapted” to certain trades and others are “dedicated” to certain trades. If, for example, you work in the aluminum industry, the KmExtrusion solution will be a more suitable answer. If you are multi-production, multi-material or if you produce small series, then a tool like KmProd will be better adapted to this type of production.

Use MES software to manage your scheduling:

The scheduling integrated in the MES software allows to recover information which will be different according to each company:

- The machine stops recovered by the MES software

- Available resources: machines, materials, human resources (planning, availability and also operator skills and authorizations)

The information of the different OFs and sub OFs - The production work in progress

- But also the variables specific to your business, which we can adapt.

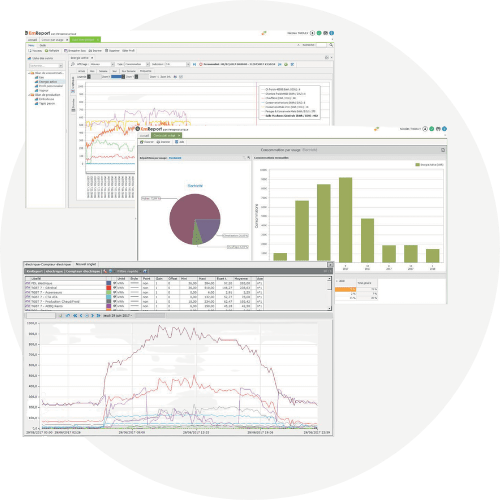

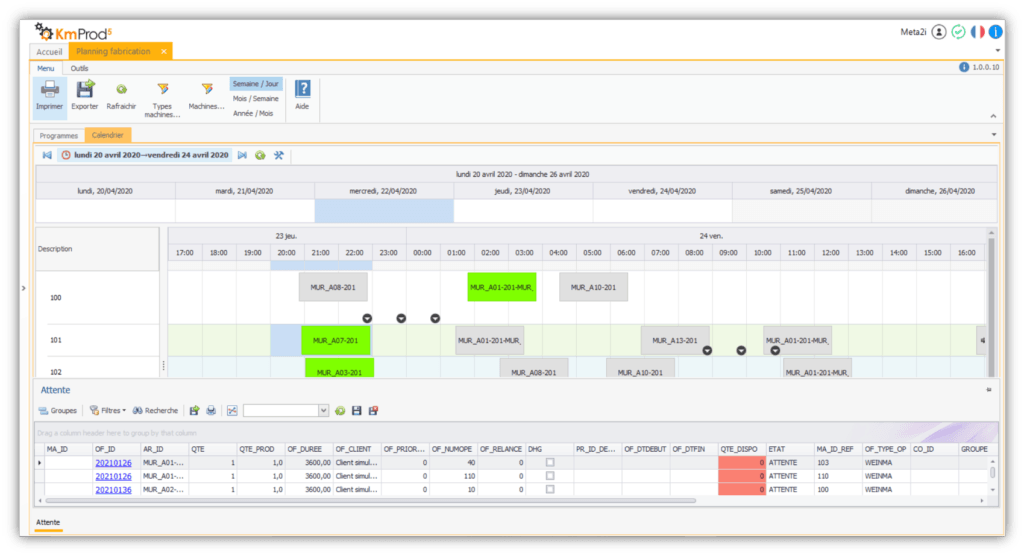

The MES software will be able to provide connected scheduling, in real time and on various terminals (laptop, mobile, tablet). The results will be displayed in the form of a Gantt chart.

Thanks to its information and in particular to the real time monitoring, the MES software will be the only category of solution to be able to automatically process production data in real time because of its ability to communicate with the sensors installed on the machines but also with the communication established with the ERP.

Go further with KmProd scheduling:

Through its MES KmProd software, META 2i offers you a scheduling system that can take into account all the constraints related to your business. Our software will adapt to your industrial process. Thus, you will be able to plan your production according to your needs without us having to develop too many specific modules. This greatly limits the costs on your side while allowing us a faster deployment speed.

KmProd distinguishes itself from its competitors by its flexibility! Adapting up to 50%, it is possible to set up KmProd whatever your sector of activity. Don’t hesitate to make an appointment with us to present us the challenge you wish to take up!