Whether it’s for your spare parts, raw materials, finished goods or any other type of equipment, you are faced with real challenges when it comes to inventory management. Let’s see how you can manage your inventory more simply and efficiently with CMMS (Computerized Maintenance Management Information System).

Your business will improve with CMMS by helping you ask the right questions and find the best answers.

Several problems can be linked to inventory management, including

Excess or overstock of spare parts,

The absence of the right parts in stock at the right time,

The lack of rigor in the storage of your parts in your stores

The effects of a CMMS on inventory management

In addition to maintaining an ideal level of parts (to reduce the value of your inventory to a minimum), CMMS allows you to track data in real time and anticipate replenishment.

Identify the most frequently used (or least used) pieces of equipment with the software’s built-in analysis tools.

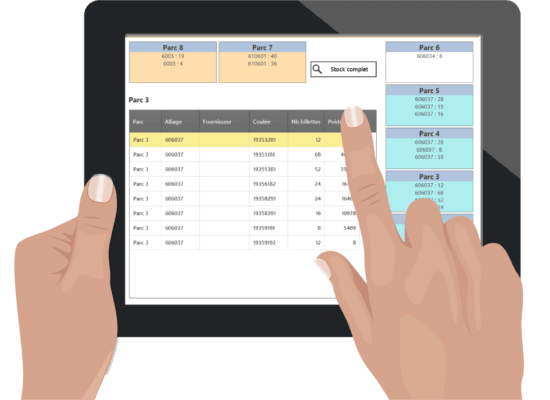

The functionalities of the CMMS for inventory management

- Detailed part sheets: interface summarizing the information needed to use the consumables.

- Traceability: part traceable thanks to a QR code or a barcode.

- Automatic replenishment: definition of a replenishment threshold allowing the automatic sending of an alert each time a part has reached its threshold.

- Management of the entries and exits of the store: history on the movements of the parts to optimize the traceability.

- Reservation of articles in the stock: action defined according to the preventive needs.

- Multi-store and multi-vendor management: movement of parts between different partners and locations is possible.

- Detailed location data: precise visibility of the location of the part sought (e.g.: warehouse 1, shelf 4, drawer 2).

- Detailed supplier files: interface to facilitate management and relations with partners.

Return on Investment (ROI)

Reduction in inventory value:

to

Reduced procurement costs:

to